Supercritical fluids represent a major advance in the field of composite materials recycling. Halfway between a liquid and a gas, these fluids reach a unique state under precise conditions of temperature and pressure, giving them exceptional properties.

Thanks to their high penetration capacity and adjustable solvent power, supercritical fluids allow the efficient separation of the different components of a composite material without altering their properties. Unlike traditional methods, which are often destructive, this technology preserves the integrity of fibers, resins and other materials.

After dismantling, the materials are recovered in their entirety without damage, in order to give them a second life.

The dismantled raw materials can be reintegrated into a production cycle or intended for recycling channels associated with each type of material, thus creating a virtuous loop.

This dismantling method is complementary to other recycling techniques such as crushing, mainly for logistical reasons.

Supercritical fluids represent a major advance in the field of composite materials recycling. Halfway between a liquid and a gas, these fluids reach a unique state under precise conditions of temperature and pressure, giving them exceptional properties.

Thanks to their high penetration capacity and adjustable solvent power, supercritical fluids allow the efficient separation of the different components of a composite material without altering their properties. Unlike traditional methods, which are often destructive, this technology preserves the integrity of fibers, resins and other materials.

After dismantling, the materials are recovered in their entirety without damage, in order to give them a second life.

The dismantled raw materials can be reintegrated into a production cycle or intended for recycling channels associated with each type of material, thus creating a virtuous loop.

This dismantling method is complementary to other recycling techniques such as crushing, mainly for logistical reasons.

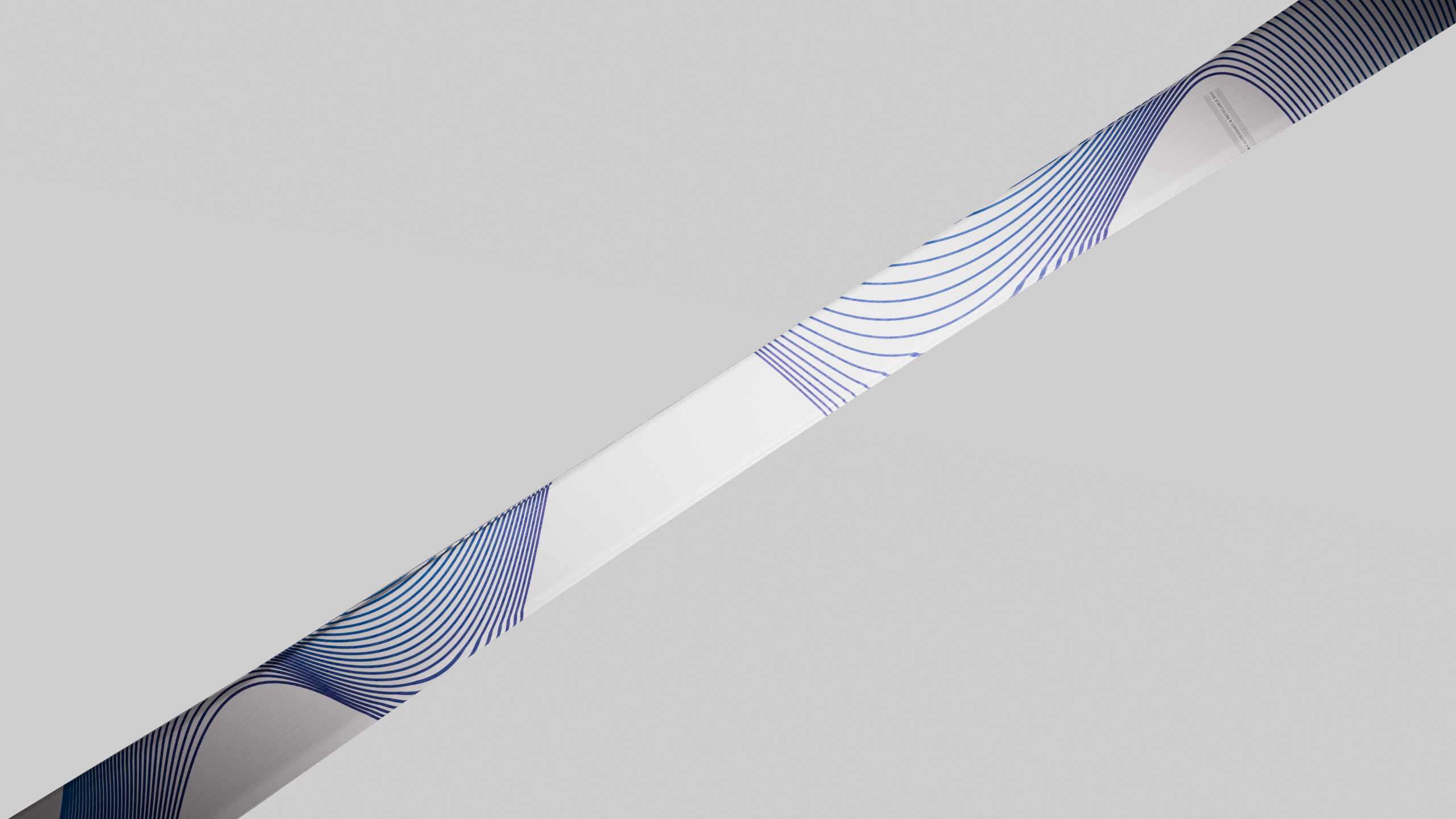

Recycle without damaging

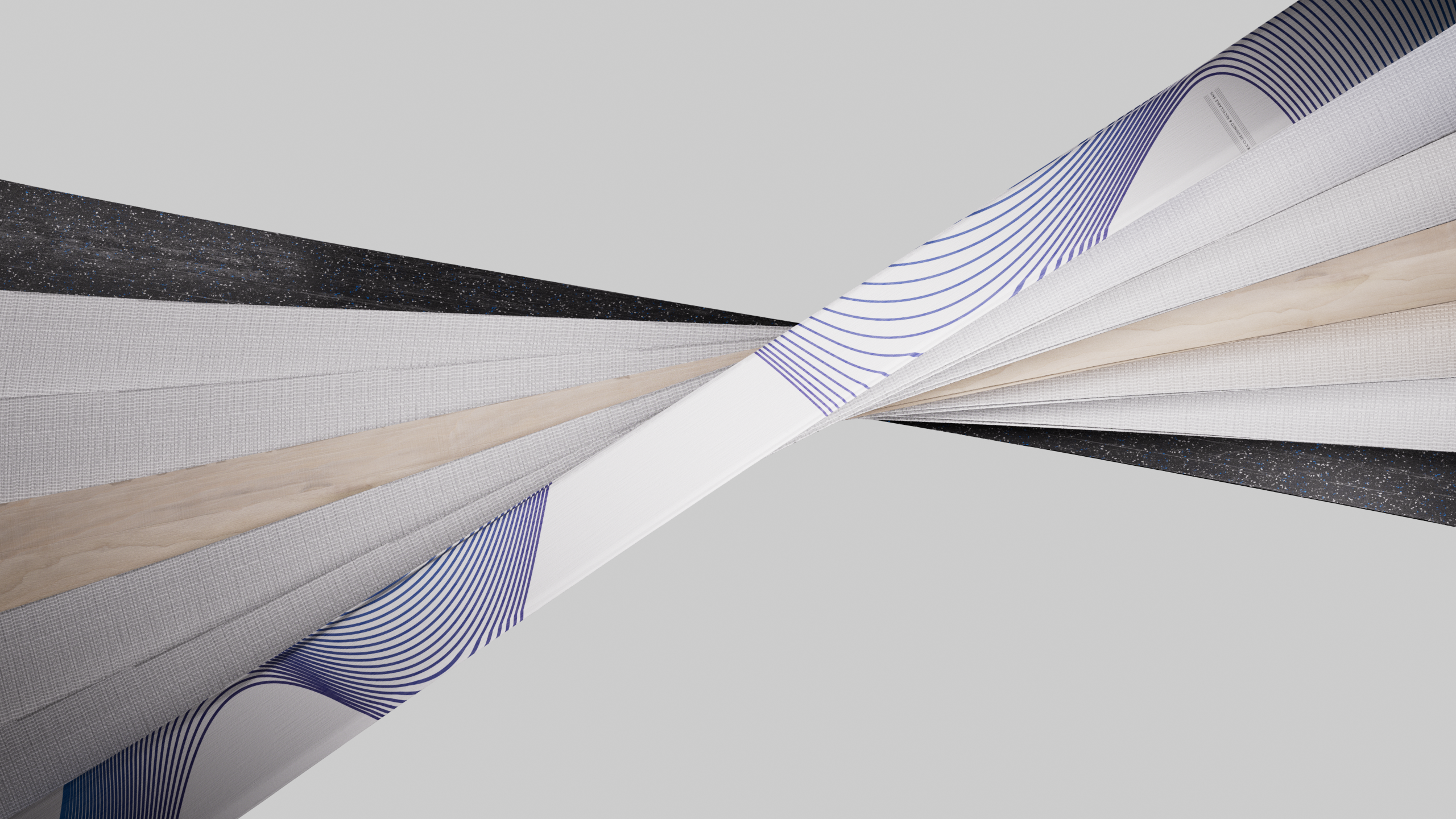

Using supercritical fluids, complex composite materials, such as the skis pictured here, are carefully separated into different layers. Each component, whether fibers, metals, polymers or other materials, is extracted and recovered. This process transforms what was once waste into a valuable resource, paving the way for a circular economy in the composite materials industry.

Before dismantling

After dismantling

CNRS x DNA

We are collaborating with the CNRS ICMCB laboratory to conduct an in-depth study on the dismantling of composite materials by supercritical fluids. This research aims to optimize component separation techniques in order to maximize their recyclability. Together, we are exploring new scientific approaches to transform waste into resources, thus contributing to sustainable innovation and the ecological transition in the composites industry.

Whether you are a recycling player looking to improve the recovery of composite materials, or an industrialist wishing to revalue these materials at the end of the cycle, we offer solutions adapted to dismantling.

Consult our equipment to optimize your operations while respecting technical and environmental requirements.

Our offer